Product Insight

Dynamics of Power Resistors

Power resistors protect technology by converting large amounts of energy into heat that can be dissipated. Designing your devices for long-term reliability requires power resistors that can withstand performance requirements.

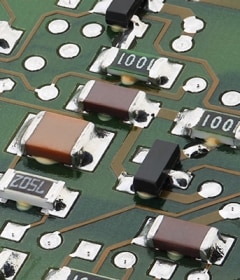

Power resistors are the workhorses of the electrical world. Unlike small chip resistors, which are mounted on printed circuit boards (PCBs) to fine-tune electronic circuits, power resistors are engineered to handle large amounts of excess energy within high-powered systems. The types of energy flow that power resistors can handle range from continuous current flow to an instantaneous power surge. Continuous flow is typified by a discharging battery, where the current can be predicted and mapped over time. In contrast, a power surge involves very high currents that are generated from either starting an electric motor or the pulse generated by a lightning strike.

How to Select the Right Power Resistor for Your Design

In contrast to chip resistors, wirewound power resistors are made to handle a high amount of energy. To achieve this, the product has significant mass because it is composed of a resistive wire wrapped around a ceramic core that is also fitted with heavy duty terminations. The resistive element in a wirewound power resistor features a large surface area, which is what gives it the capacity to dissipate the heat generated when a current is passed through it.

To support this, wirewound power resistors are mounted into a case equipped with cooling vanes to optimize thermal management. Although the amount of material does result in a device that is quite large this design is what enables it to resist as much as 1000 watts of power.

For more efficient dissipation of heat energy, all power resistors can be used in conjunction with a heat sink. A heat sink can be a dedicated device, designed with a large surface area which serves to maximize heat-loss performance. It is possible that a clever design could eliminate the need for a separate heatsink.

For example, by mounting the power resistor onto a frame or enclosure, designers can use the entire body of a device as a heatsink. Whichever method is adopted, it is worthwhile to note that using a heatsink can increase the energy capacity of a wirewound power resistor by as much as 300%.

Before specifying power resistors, the designer must fully understand the application’s power requirements. An efficient way to start determining the need is to analyze the scale of the electrical load that the resistor will need to manage. Determining this is complicated by the nature of the current. When considering the use of a continuous electrical current, designers need to analyze the energy load in terms of watts – the energy required to be dissipated per second. For an instantaneous load, such as a lightning strike, they need to analyze total energy load in Joules.

A good example of using large power resistors in continuous use is the power system in electric and hybrid vehicles. These vehicles are powered by systems that use a large amount of high-voltage current, as high as several hundred amps. This level of high current poses significant risks, particularly when it comes to maintenance, as the battery will retain its charge even when the car is turned off. Before a mechanic can work on the vehicle, they need to safely discharge the battery. Using large wirewound power resistors in the battery technology enables mechanics to do this, because the design will effectively convert excess electrical power into heat.

Understanding the power requirements of your technology is critical. This will enable you to select the type of power resistors which can create the safe, reliable electrical circuit needed to manage the energy in the device.

After you know what you need, browse our broad portfolio of power resistors to find the right solution for your design. You can also contact our product specialists to learn how we can help you determine your power requirements.

e

e

e

e

e

e

e

e

e

e